Excel Industries saw the demand for their most popular zero-turn mowers skyrocket. The increase in demand was great news and meant the South-Central Kansas company needed a facilities review and supply chain revision. They realized when they forecasted demand that they would need to expand to increase production while consolidating locations to improve inventory management. They began looking for potential warehouse close to the Kansas City market.

Excel Industries sought a partner they could trust to outsource for expertise in warehouse layout, daily warehouse management and WMS capabilities. Their research and referrals directed them to Wagner Logistics, with 70 years of experience, and prompted meetings and discovery to ensure both capability and a cultural fit.

The groundskeeper blueprint

Wagner Logistics brought extensive 3PL resources, an experienced team with decades of knowledge, and the latest technology (IT-in-a-Box) to Excel Industries with a plan to outsource and streamline distribution. The brand new warehouse near Kansas City was fully functional within a few months. IT-in-a-Box was deployed to accelerate the startup time. IT-in-a-Box runs on a secured private network to provide connectivity throughout the warehouse without having to wait for permanent lines and wiring to be installed.

The greenest lawn on the block

Moving the finished goods out of a rural location to a better transportation and warehouse market helped bring transportation rates down. Excel was able to use current staff for other manufacturing positions to aid in the required production increase. Outsourcing eliminated the need for staging, finished goods were moved to an improved storage environment, reduced inventories and removed bottle necks at the end of production lines.

Daily production continued to increase throughout the transition. The facility consolidation reduced duplicate inventory in multiple locations resulting in fewer back orders. Part of the quality assurance was moved to the new facility allowing Excel to handle rework offsite versus taking up manufacturing space at the plant.

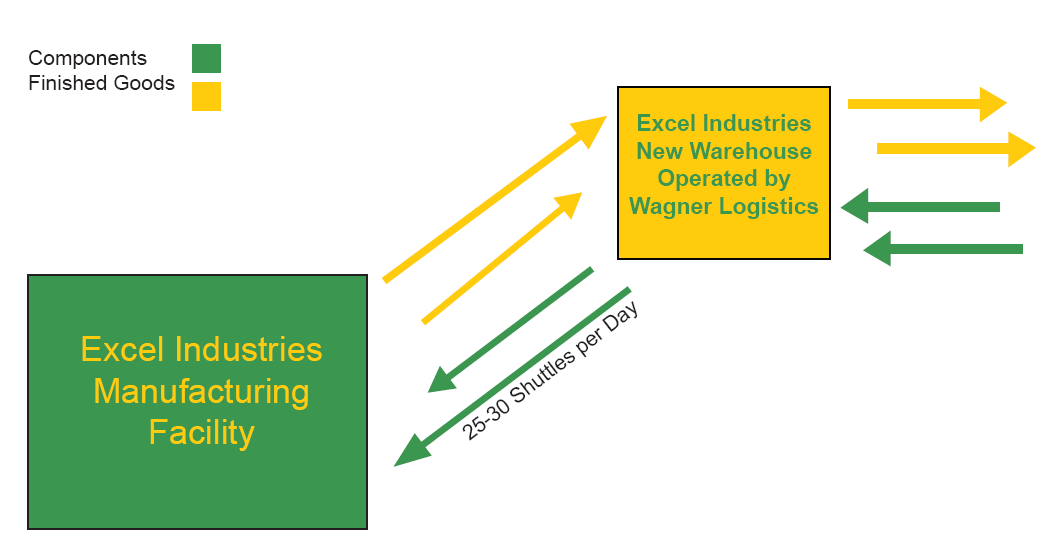

Several of the components used in the production of the mowers are strategically being transferred to the Kansas City area to free up more space at the main production site. The production facility carries 1-3 days of components, which are delivered to the production facility during off-peak production times, to optimize labor planning. Vendor shipments are less frequent and a higher quantity can be ordered with a better overview of overages and shortages. Wagner runs 25-30 shuttles a day from the Kansas City area to the production facility to keep onsite inventory level stocked, delivering component parts and returning with finished goods.

Excel has recognized a 37 percent production growth during the transition, consolidated multiple DCs and moved to a superior freight market using Wagner transportation. Excel has gained better visibility for raw materials and finished goods while maintaining complete control & confidence through outsourcing. Wagner helped Excel achieve their three main goals and provides peace of mind.